The Growing Demand for High-Speed Fastener Packaging in Industrial Sectors

In today’s fast-paced industrial landscape, fastener manufacturers face intense pressure to deliver high volumes of screws, nuts, bolts, washers, and other components with speed, precision, and consistency. With global demand expected to drive the fastener market beyond $120 billion by 2027 (Source: Grand View Research), companies must scale production without compromising quality or efficiency.

For many fastener manufacturers, the packaging stage has become the new bottleneck. While advancements in forging, threading, and plating have optimized the upstream process, many factories still rely on outdated or manual packaging systems. These traditional methods are labor-intensive, error-prone, and inadequate for today’s high-volume output expectations.

In this context, fastener packaging machines are no longer an alternative, but a strategic necessity. By automating the packaging process, manufacturers can increase production, improve counting accuracy, reduce labor costs and ensure product consistency.

The Manufacturing Challenge: Scaling Output Without Sacrificing Efficiency

Fastener manufacturers in industries such as automotive, aerospace, furniture, and construction operate under tight production schedules. They deal with:

- Thousands to millions of parts daily

- Multiple product SKUs and fastener specifications

- High product mixing complexity

- Strict quality assurance protocols

Manual packaging methods often involve:

- Workers manually counting or weighing parts

- Using plastic bags and sealing them by hand

- Labeling and boxing performed on separate lines

These practices lead to inconsistent counts, slower production, higher error rates, and increased labor costs. More importantly, manual packaging introduces variability that undermines the overall supply chain—causing overpacking, underpacking, or damaged shipments.

To remain competitive, fastener producers must automate packaging operations in a way that aligns with their existing production flow.

The Role of Fastener Packaging Machines in High-Volume Production

What is a Fastener Packaging Machine?

A fastener packaging machine is a fully or semi-automated system designed to count, sort, and package fasteners—such as screws, bolts, nuts, washers, anchors, and clips—into bags, boxes, or kits. These machines can be tailored for single-type packaging or multi-component hardware kits, depending on the application.

Modern fastener packaging systems typically include:

- Vibratory feeders for precise part separation

- Counting sensors or weighing modules

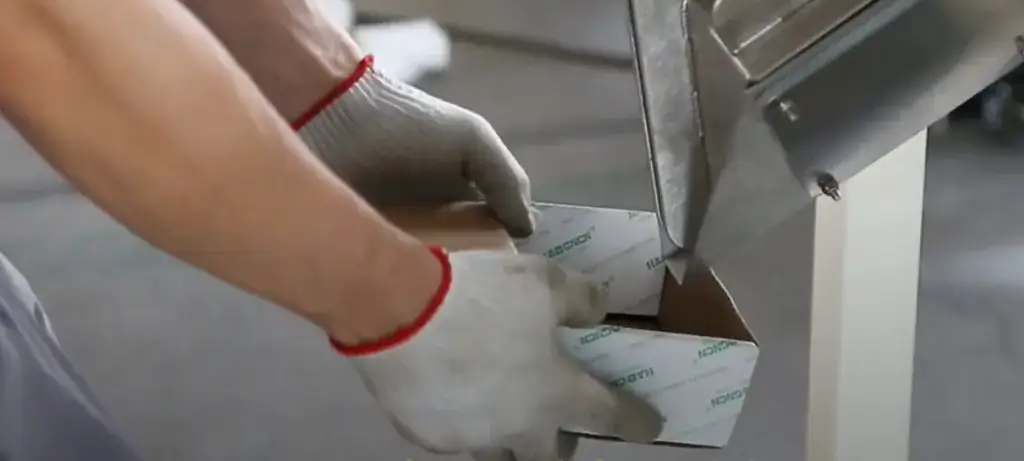

- Bagging units or boxing stations

- Label printers and applicators

- Checkweighers and reject mechanisms

- Touchscreen PLC interfaces for control

Key Benefits for Fastener Manufacturers

1. High-Speed Output

Automated machines can package thousands of items per hour, running continuously with minimal supervision. This dramatically increases daily throughput compared to manual packaging.

2. Precision and Count Accuracy

Advanced counting systems (photoelectric, weighing, or combination) ensure that each package contains the exact number of parts, reducing overpacking (losses) or underpacking (customer complaints).

3. Reduced Downtime

Quick-change tooling, intuitive touch panels, and modular designs mean that changeovers for different fastener types take minutes—not hours—keeping production flowing.

4. Labor Cost Reduction

One operator can manage several packaging lines, reducing your reliance on manual labor and lowering long-term staffing costs, especially in high-wage regions.

5. Improved Quality Control

Integrating checkweighing and vision inspection allows manufacturers to catch missing or incorrect items before they reach the customer.

6. Better Inventory and Data Management

With integrated PLCs and IoT connectivity, many machines provide real-time production data, which helps with inventory tracking, order fulfillment, and predictive maintenance.

Application Scenarios in the Fastener Industry

Automotive Sector

Manufacturers must deliver complete kits of fasteners for assembly lines—often just-in-time. Packaging machines ensure that each kit contains the right components, labeled and ready for use.

Furniture & DIY Hardware

Fasteners packaged with furniture need clear labeling, consistent counts, and damage-free presentation. Packaging machines handle mixed kits for flat-pack furniture with ease.

Construction and Heavy Machinery

Bulk quantities of anchors, screws, or bolts must be packaged into strong, durable bags or boxes. High-speed systems reduce the time between production and dispatch.

Aerospace and Precision Engineering

In industries where every fastener must be traceable, packaging machines can include labeling systems with QR codes, batch numbers, and tracking details.

Selecting the Right Fastener Packaging Machine What to Look For

When evaluating a packaging machine for your manufacturing plant, consider the following:

| Feature | Benefit |

|---|---|

| Multi-channel counting systems | Handle various sizes and materials with accuracy |

| Bagging or cartoning options | Choose packaging type depending on distribution model |

| Modular design | Upgrade or reconfigure based on future needs |

| Touchscreen control panel | Easy for operators to learn and use |

| Low maintenance design | Reduce repair downtime and spare parts inventory |

| Custom kitting functions | Assemble different fastener types into one package |

Also, consider after-sales support, spare parts availability, and the supplier’s experience in the fastener industry.

How Automation Helps You Compete in a Global Market

In global markets, price and delivery speed are everything. Clients expect fasteners to arrive:

- Correctly counted

- Properly packaged

- Labeled according to international standards

- Delivered with zero defects

By integrating a fastener packaging machine into your production line, you can comply with customer expectations, scale output without proportional cost increases, and gain a competitive edge through better service and reliability.

Real-World Case Study

Feiyu Packaging recently partnered with a mid-sized furniture hardware supplier facing high labor costs and increasing order volumes. By integrating a 4-channel automatic counting and bagging machine, they reduced packaging labor by 60%, improved order accuracy to 99.8%, and saw a full ROI in under 18 months.

Shanghai Feiyu: Custom Fastener Packaging Machine Solutions

At Shanghai Feiyu Packaging Machinery, we have over 17 years of experience providing automated solutions for the fastener industry. We offer:

- Screw and bolt packaging machines

- Multi-component hardware kit packaging

- Boxing and sealing machines

- Customized feeders and vibrators

- Checkweighers and reject systems

- Global support and training

Whether you produce small screws, large anchors, or diverse kits of fasteners, we can build a solution tailored to your product specifications, volume requirements, and factory layout.

Our machines are designed to perform reliably in dusty, vibration-heavy, and high-temperature industrial environments. We also provide remote diagnostics, spare parts support, and operator training to keep your lines running smoothly.

Make Packaging Your Competitive Advantage

For fastener manufacturers, packaging is more than the final step—it’s a key part of customer satisfaction, brand presentation, and operational efficiency. As demand grows and competition intensifies, investing in a high-performance fastener packaging machine can help you:

- Meet high-volume production goals

- Reduce waste and labor costs

- Deliver products with unmatched accuracy

- Improve supply chain responsiveness

Ready to transform your packaging process?

Contact us today to get a free consultation and discover the right packaging solution for your fastener business.