Application

- Fasteners: Screw, Bolt, Nut, Washer, Rivets, Nails Etc.

- Plastic/Rubber Parts: Wall Anchor, Rubber O-Rings, Toys, Lego Building Bricks, Small Plastic Parts.

- Hardware Parts: Hardware Components, Hardware Connectors, Metal Parts Etc.

- Furniture Accessorles: Furniture Connectors, Furniture Fasteners, Furniture Fittings, Furniture Accessories, Door Handle, Hinge Etc.

- Others: Small Hardware or Plastic Parts, Regular Shape or Irregular Shape of Parts.

Samples

Not only for screws, but also for other small hardware components such as nuts, bolts, washers and plastic parts, making it a versatile asset in your packaging system.

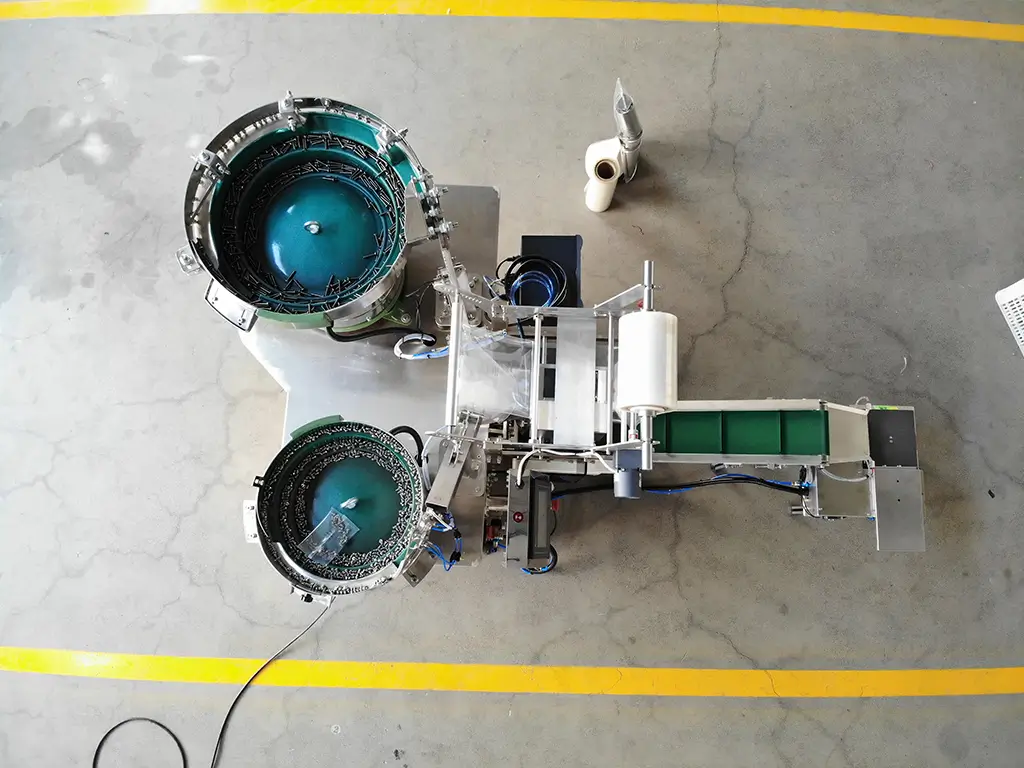

Double bowl design

The double bowl system can process nuts and bolts of different specifications at the same time, improving production efficiency. Through precise counting and distribution functions, it ensures that the quantity in each packaging bag is exactly the same to avoid waste.

PLC Control System

7 inch touch screen, easy operation and multiple language for choice.

Automatic counting and packaging

Equipped with a high-precision fiber counting device, it automatically counts the number of screws to ensure accurate packaging. It then fills the predetermined quantity into each package, providing a reliable and consistent output.

Adjustable parameters

Packaging parameters such as packaging quantity, speed, bag size, etc. are easy to set to suit various production requirements and adapt to different types of screws and hardware.

Bag making system

The system can automatically make bags from rolls and adjust bag size, sealing method, etc. according to product requirements

Model

| Model | FY-240A-2 | FY-420A-2 |

| Packing size | L: 30-180mm, W: 50-140mm | L: 50-300mm, W: 50-200mm |

| Max film width | 300mm | 420mm |

| Packing material | PA/PE, PP/CPP, PET/PE | |

| Counting capacity | 1-20 pcs/bag; 1-2 types/bag | |

| Packing speed | 10-40 bag/min | |

| Power | AC220V/50-60Hz/2kW | |

| Machine size | 1500mm(L)* 1200mm(W)* 1650mm(H) | |