Multifunctional automatic screw counting and packaging machine

The Automatic Screw Counting Packing Machine is a highly efficient and intelligent packaging solution designed to accurately count and pack a variety of small hardware items, especially screws, bolts, nuts, washers, and other fasteners. This machine integrates automatic feeding, counting, filling, sealing, and output into a streamlined process, reducing labor costs and improving production efficiency.

Built with a user-friendly interface and robust construction, this machine is ideal for hardware manufacturers, fastener suppliers, and furniture accessory factories that require high-speed, accurate, and reliable packaging operations.

Key Features

1. High-Precision Counting System

The machine uses advanced photoelectric sensors and microcomputer-controlled counting modules to ensure that every package contains the exact number of screws required. Whether packing 10, 20, or 100 screws per bag, the system maintains high accuracy and consistency.

2. Flexible Configuration Options

You can customize the number of counting channels according to your production requirements. The machine typically supports 1–40 vibrating bowls or linear feeders, allowing for:

- Single-type screw packing

- Mixed-type screw combinations in a single bag

This flexibility is ideal for products like furniture hardware kits or DIY home assembly kits.

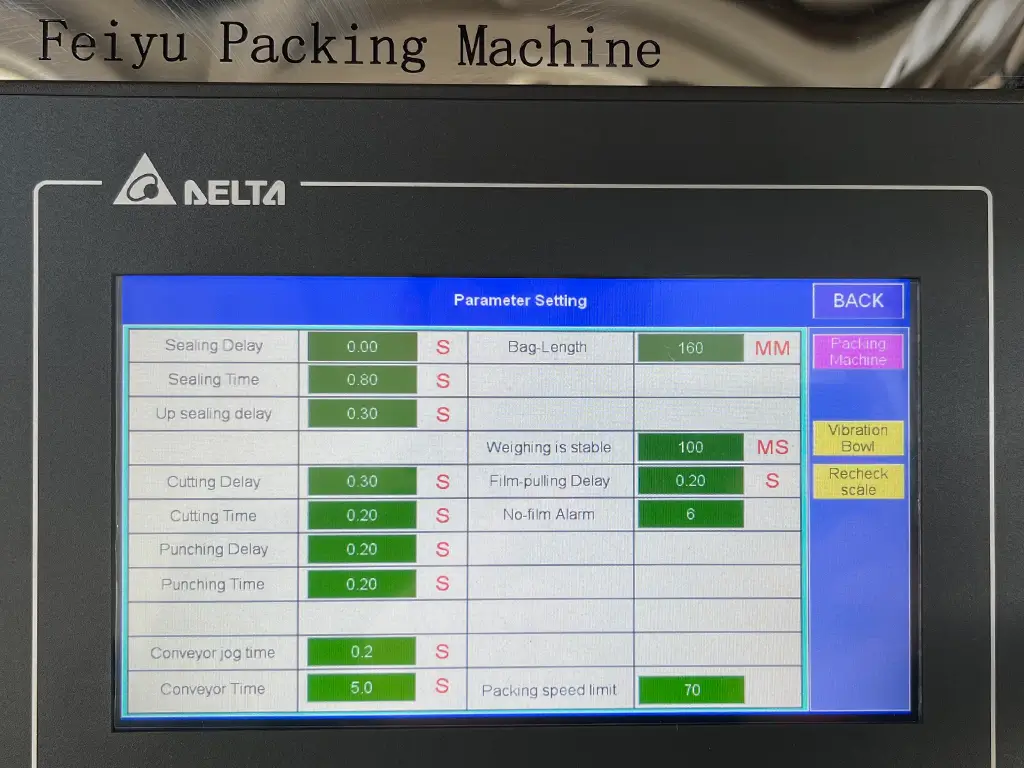

3. Touchscreen Operation Panel

Equipped with an intuitive HMI (Human-Machine Interface), operators can easily set parameters such as:

- Counting quantity

- Bag length

- Sealing temperature

- Output speed

Language options and recipe memory functions simplify operation and reduce setup time during product changes.

4. Durable Packaging Materials Support

Compatible with a wide range of packaging films including:

- PP/CPP

- PA/PE

- PET/PE

- PE

Laminated films

This allows for durable and visually appealing retail-ready packaging.

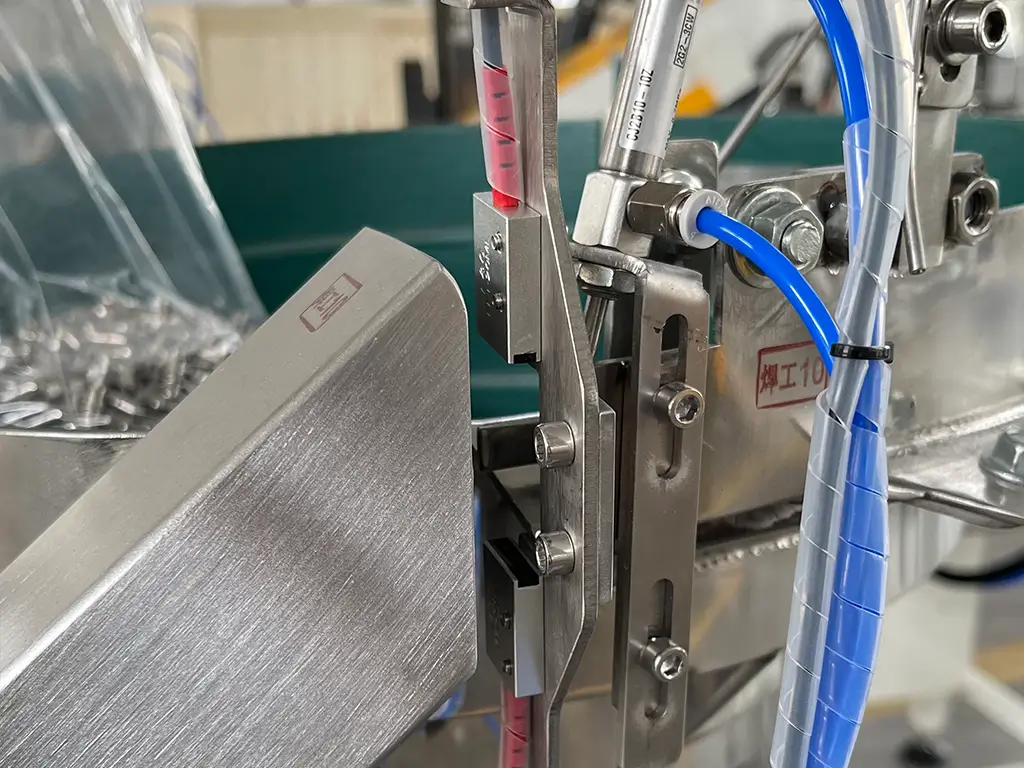

5. Compact and Modular Design

The compact design ensures efficient use of floor space. Modular construction makes it easy to integrate with conveyor belts, labeling systems, boxing machines, or checkweighers as part of a complete packaging line.

Packaging sample

This machine supports the packaging of a variety of hardware, such as screws, nuts, bolts, washers, etc., to meet the counting and packaging needs of various hardware products.

Versatile Applications:

- Hardware manufacturers: Suitable for companies that produce and package various screws, bolts, nuts, washers and other fasteners.

- Assembly line operations: Simplify the packaging process of fasteners in the assembly line and improve production efficiency.

- E-commerce packaging: Designed for packaging screws and small hardware components for quick distribution to customers.

- Furniture accessories: Efficient packaging of furniture parts such as screws, nuts and other components.

- Plastic pipe fittings: Suitable for packaging plastic pipe fittings such as pipes and joints to ensure efficient counting and accurate packaging.

- Automotive parts: Packaging various fasteners and small parts in the automotive industry to provide accurate counting.

- Mechanical and electrical parts: Packaging various mechanical and electrical components to adapt to products of different sizes and shapes.

- Clothing parts: Packaging of small clothing parts such as buttons and sliders to meet the needs of efficiency and precision.

- Toy industry: Suitable for packaging toy components, Lego bricks, construction toys.

Parameter

Model | FY-240C | FY-420C |

Packing size | L: 30-180mm, W: 50-140mm | L: 50-300mm, W: 50-200mm |

Max film width | 300mm | 420mm |

Packing material | PP/CPP,PA/PE,PET/PE,PE, | |

Counting capacity | 1-20pcs/bag; 1-40 kinds/bag | |

Packing speed | 10-60 bag/min | |

Power | AC220V/50-60Hz/2kW | |

Machine size | L*W*H: (n/2*600+2200mm)* 1500* 1650mm, n=the Qty of vibration bowl | |

Video

Why Choose Our Screw Counting Packing Machine

✅ High Efficiency

Achieve up to 60 bags per minute with accurate counting and minimal downtime.

✅ Cost Reduction

Automates manual packing processes, saving labor and reducing errors.

✅ Customizable Design

Support for mixed product packaging, logo printing, hanging holes, and easy-open notches.

✅ Minimal Maintenance

Stable performance with low maintenance requirements due to quality components and electrical systems from trusted brands (e.g., Omron, Siemens, Schneider).

✅ Intelligent Alarm System

Automatic stop and alarm functions in case of:

- No material

- Incorrect count

- Packaging film shortage

- Overload or mechanical fault

✅ Integration Ready

Compatible with weighing machines, cartoning machines, and labeling machines for complete production lines.

Optional Add-ons

To further enhance productivity, the following modules can be integrated:

- Checkweigher – Rejects unqualified bags with incorrect weight.

- Label Printer – Adds QR codes, barcodes, or product info.

- Automatic Feeding System – Reduces manual material refilling.

- Boxing Machine – For packing multiple bags into cartons automatically.

After-Sales Service & Support

Shanghai Feiyu Packaging Machinery provides comprehensive after-sales service including:

- Installation and commissioning support

- Operation training for staff

- Lifetime technical support

- Spare parts supply

- Online troubleshooting (via video call/email/chat)

Our team ensures a quick response within 24 hours to any support request.